Interactive Matter uses a wide array of skills and technologies to create prototypes and installations.

We specialise in early-stage prototyping. Having our background in design, we are able to rapidly translate (rough) ideas into functional systems that can be used as evaluation prototypes or (temporary) installations.

We are able to cover various aspects of the system design such as the system architecture, electroncis, (embedded-) software and (electro-) mechanical components.

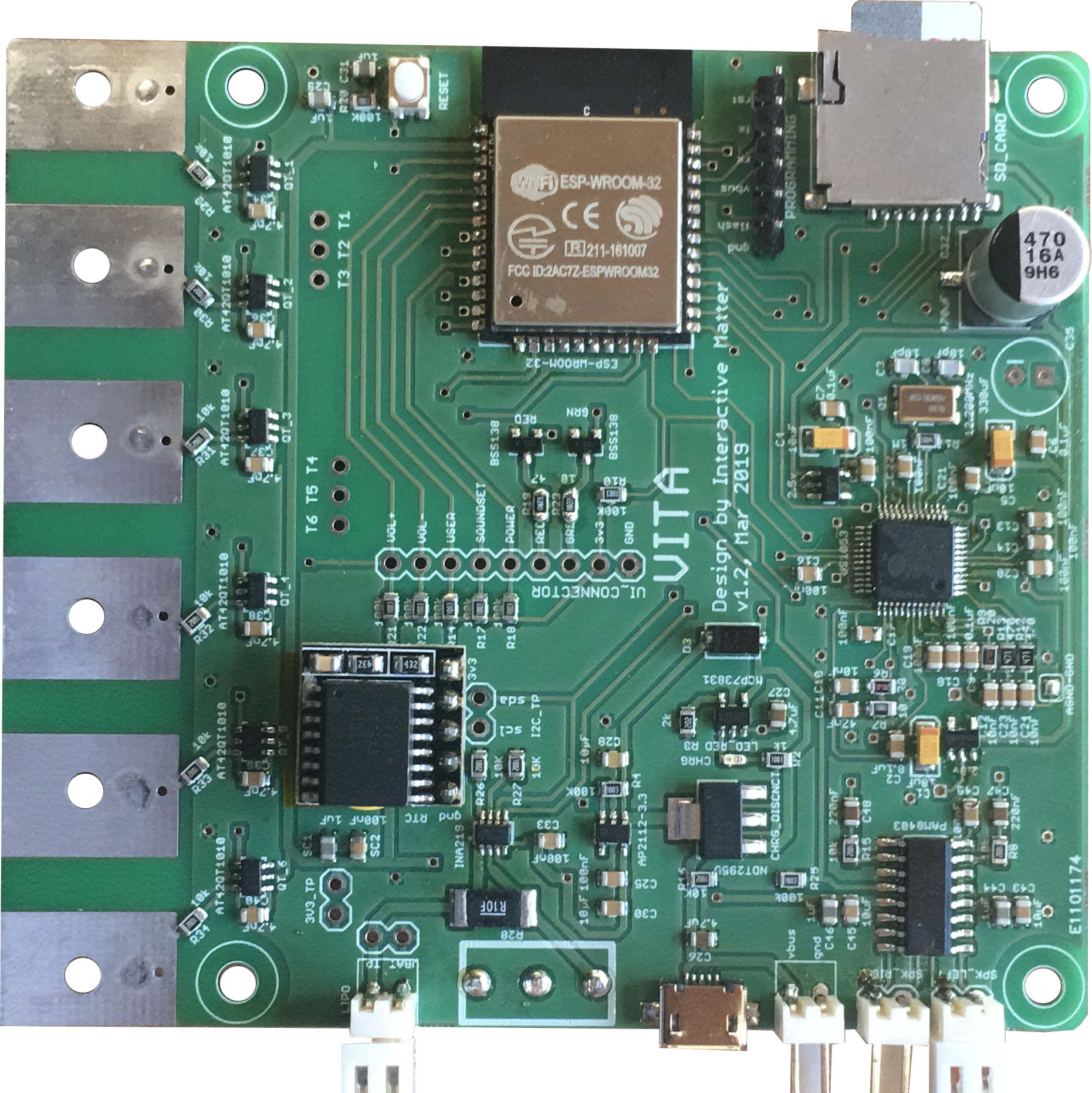

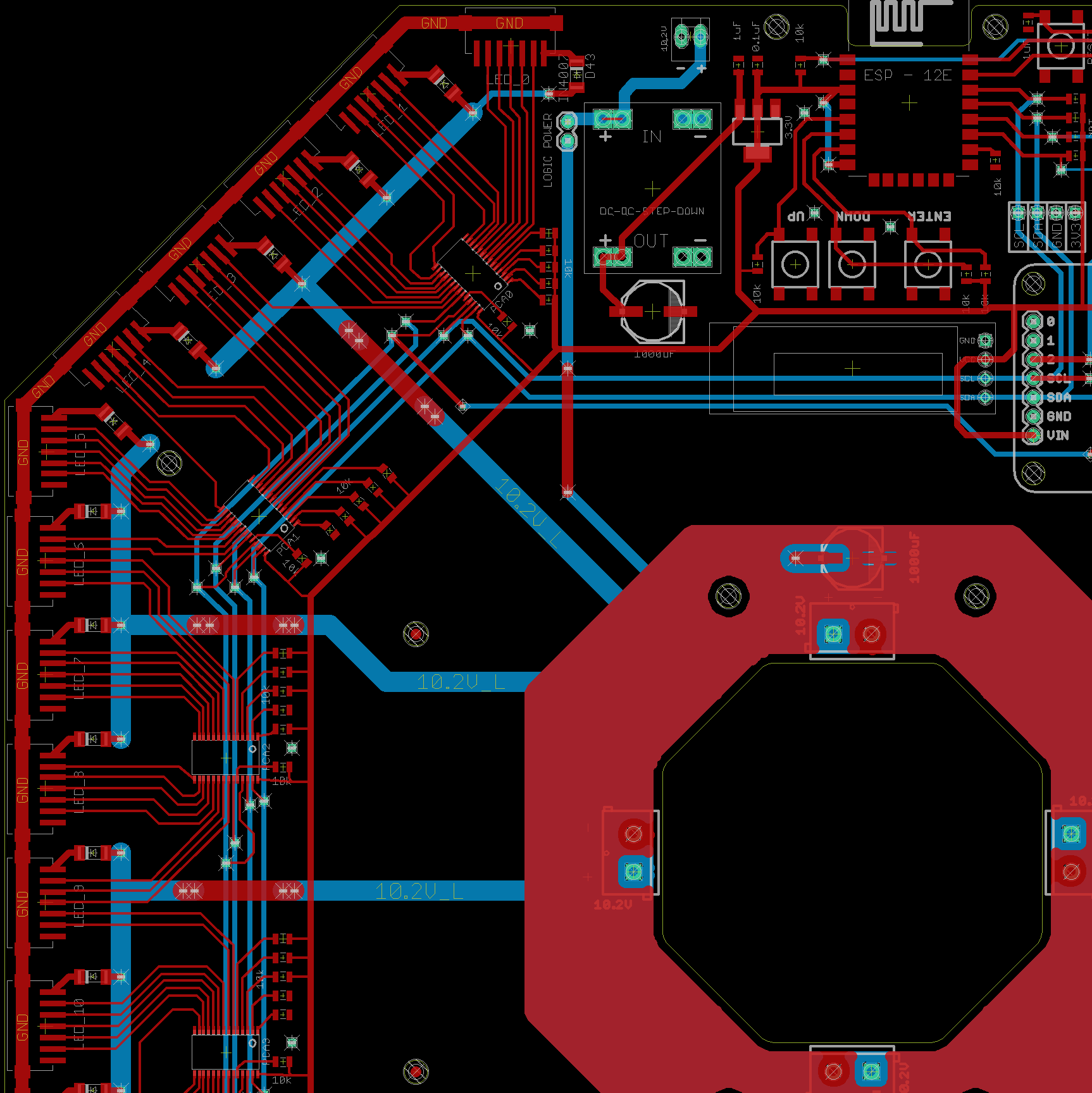

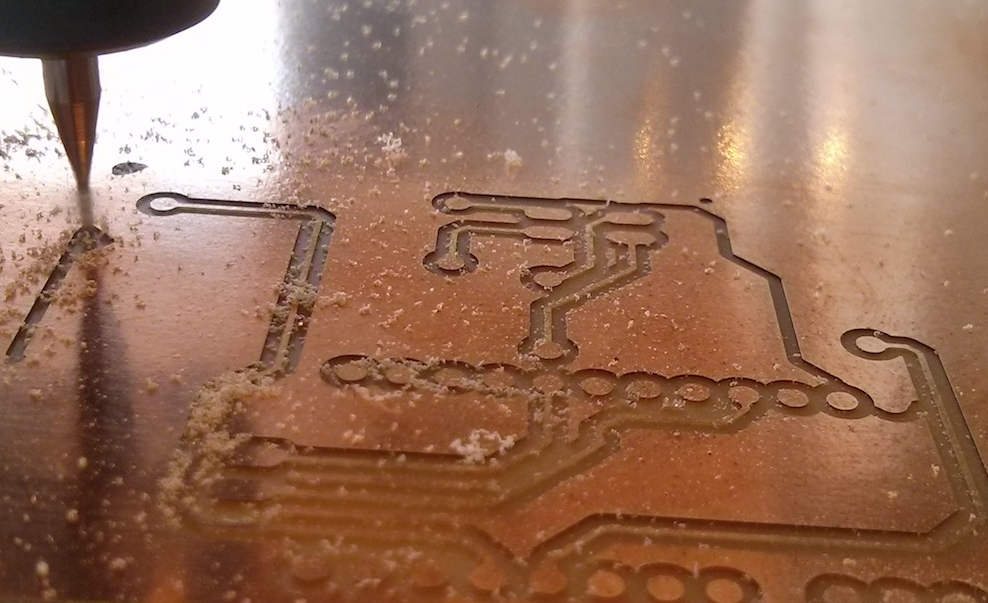

Projects start out with a system architecture design; defining all required system elements and their relations. This is subsequently translated into an electronics design and finally a PCB (Printed Circuit Board) Design.

We also develop the necessary software in house. We are skilled in a wide variety of programming languages and frameworks based on the language families C, Java, Python, JavaScript.

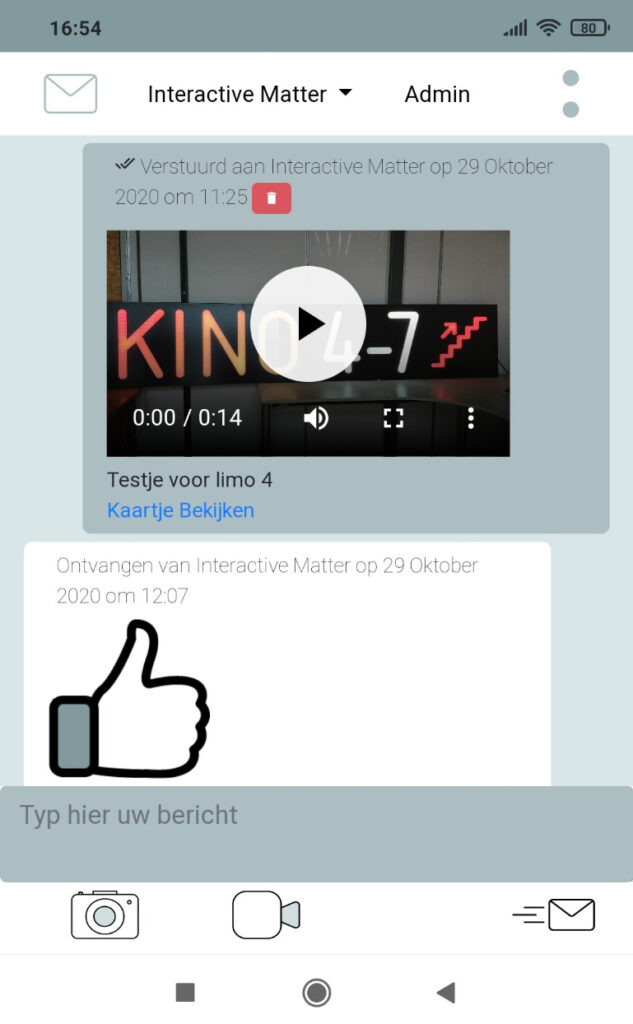

We create embedded software (for microprocessors and mini-computers such as Raspberry Pi) for the interaction with sensors and actuators, as well as software for web, apps, pc or mobile to provide user interaction at a distance.

As systems often comprise various elements, we usually deal with some form of (wireless) connectivity between components, for which we often create custom communication protocols on top of WiFi, bluetooth or other Radio Frequency communication systems.

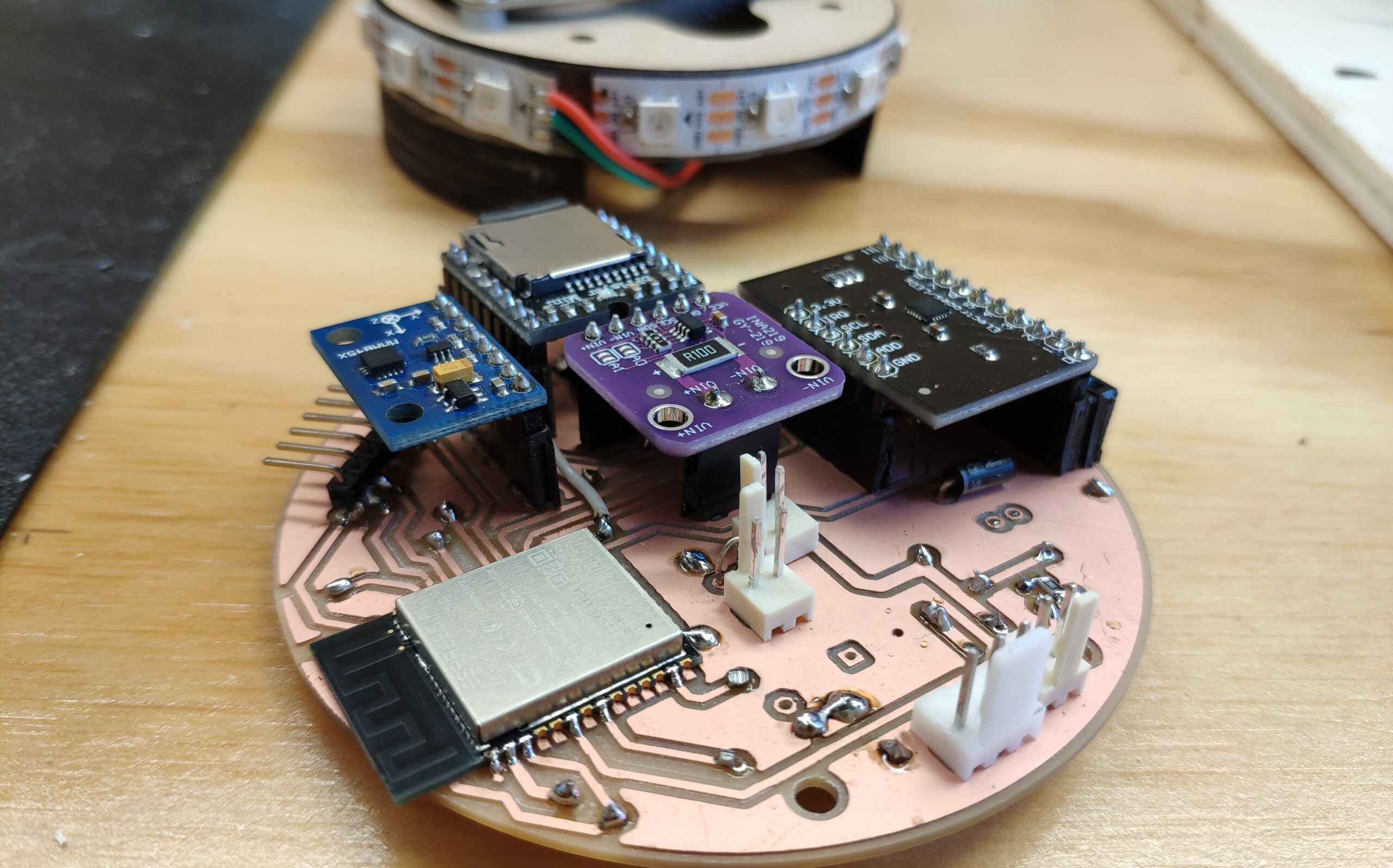

To be able to provide a rapid development process we have a large toolkit at our disposal. We have a large stock of many different processors, sensors and actuators that we can immediately use to create initial test setups.

To aid further rapid development of our electronics designs, we use our PCB router to create our PCBs in-house. For small batch assembly of PCBs, we use our pick-and-place machine.

Finally to create the mechanical components, we use various (3D) CAD techniques that we later use for lasercutting, 3D printing or other production techniques.